The Power Brush Machines System

As an owner of a Power Brush Machine system, you'll save time and money! Gone are the days of using messy fluids and wire brushes to clean drill pipe threads, tubing, and casing. The PBM system cleans threads in under 20 seconds - it doesn't get much easier than that!

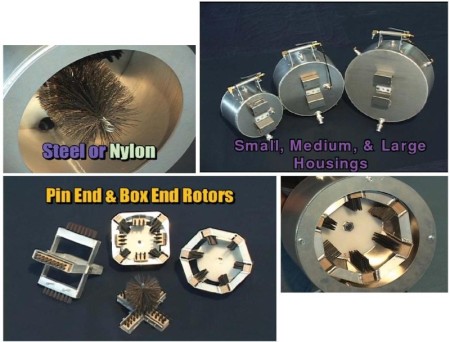

Housings and Rotors

Power Brush Machines are versatile and self-contained drill pipe thread, tubing, and casing cleaning systems. PBM cleaning components (housings and rotors) come in a variety of sizes. Housing systems are available in small, medium, and large, and are make of lightweight aluminum. A drain is attached to each housing so cleaning fluid is recaptured.

Internal pipe threads can be cleaned with a flue brush mounted onto the system, and larger diameter pipes can be cleaned with our special box-end rotor. Pin-end rotors are used to clean external pipe threads. The brushes for box-end and pin-end pipes are replaceabe and are available in steel or nylon.

Additional Components

You can customize your Power Brush Machine to come with a cleaning fluid holding tank and air & fluid hoses. Each housing is equipped with a fluid control valve in the handle that allows the user to control the amount of cleaning solution released from the tank, and also has a pneumatic motor to maximize cleaning ability.

Power Brush Machines are mobile systems; you simply connect them to your air compressor to begin use.